Industry News

Mar 06,2026

What are the applications and advantages of PTFE Etched Tube?

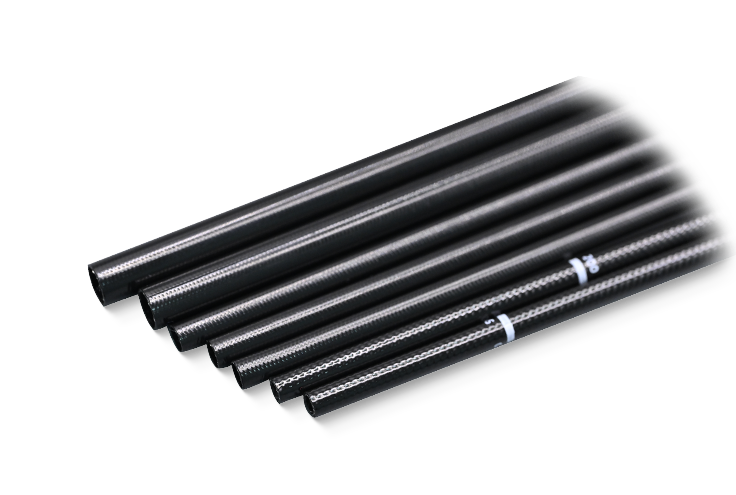

PTFE Etched Tube is primarily used in high-precision medical device manufacturing, including cardiovascular catheters, vascular stents, and neural implants. Its core value lies in combining ultra-low friction with outstanding biocompatibility and chemical resistance—making it indispensable wherever tubing must glide smoothly inside the human body without triggering adverse reactions. Applied via chemical etching to catheter outer diameters and used alongside FEP heat-shrink tubing, PTFE Etched Tube forms a durable inner lumen lining that dramatically reduces friction while maintaining structural integrity.

What Is PTFE Etched Tube and How Is It Made?

PTFE (Polytetrafluoroethylene) Etched Tube is a specialized fluoropolymer tube whose outer surface has been chemically treated to enhance bonding capability. In its natural state, PTFE is notoriously difficult to bond to other materials due to its non-stick properties. Chemical etching—typically using sodium naphthalene or similar reagents—modifies the surface at the molecular level, creating reactive sites that allow adhesives and coatings to form a strong bond.

In medical device applications, the etched PTFE tube is coated onto the outer diameter (OD) of catheters and then paired with FEP (Fluorinated Ethylene Propylene) heat-shrink tubing. When the FEP shrinks under heat, it encapsulates the PTFE liner and locks it tightly in place, forming a smooth, low-friction inner lumen. This two-material construction is widely used across interventional and surgical catheters.

Key Applications of PTFE Etched Tube

PTFE Etched Tube is used extensively across cardiovascular and neurosurgical disciplines, where precision and biocompatibility are non-negotiable. Below are the primary application areas:

Cardiovascular Catheters

In cardiac catheterization procedures, the catheter must navigate tortuous arterial pathways with minimal resistance. PTFE Etched Tube provides the low-friction inner lining that allows guide wires and balloon catheters to advance smoothly, reducing procedural time and minimizing vessel trauma. Its chemical inertness ensures it does not react with contrast media, saline flushes, or blood components.

Vascular Stent Delivery Systems

Stent delivery catheters require precise pushability and trackability. The PTFE liner reduces the friction between the stent and the catheter wall, enabling controlled, accurate stent deployment. In coronary and peripheral vascular interventions, this can be the difference between a successful placement and a procedural complication.

Neural Implants and Neurosurgical Devices

In neurosurgery, PTFE Etched Tubes are used in deep brain stimulation (DBS) leads, ventricular shunts, and other neural implants. The material's excellent dielectric insulation (dielectric strength approximately 60 kV/mm) protects sensitive electrical signals, while its biocompatibility minimizes tissue reactivity over long-term implantation periods.

Diagnostic and Interventional Endoscopy

PTFE-lined working channels in endoscopes and bronchoscopes benefit from the material's chemical resistance, especially when exposed to enzymatic cleaning agents and disinfectants. The non-stick surface also prevents biological deposits from adhering to the lumen wall.

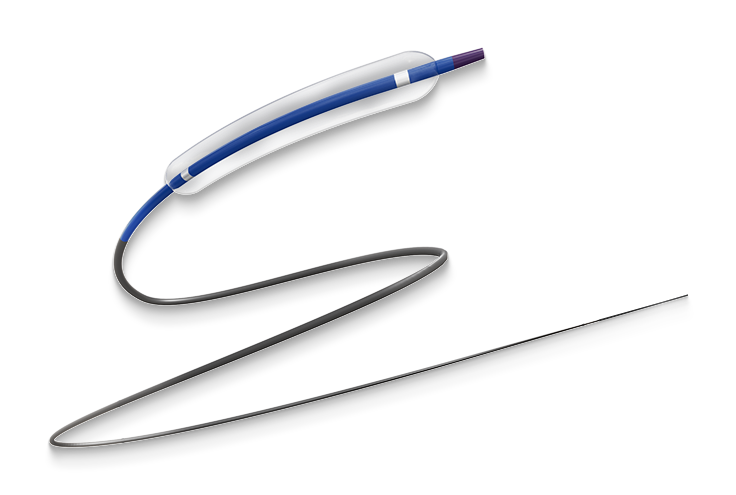

Drug-Coated Balloon (DCB) Catheters

In drug-eluting balloon systems, the PTFE liner ensures smooth balloon folding and unfolding during inflation while remaining chemically inert to the drug coating, preserving drug efficacy during delivery.

Six Core Advantages of PTFE Etched Tube

The following table summarizes the six primary performance advantages and their relevance to medical device engineering:

Table 1: Core performance advantages of PTFE Etched Tube and their medical device relevance

Advantage

Key Parameter

Application Benefit

Optimal Lubricity

Coefficient of friction as low as 0.04

Smooth catheter navigation in vessels

Biocompatibility

ISO 10993 compliant

Safe for long-term implantation

Dielectric Insulation

~60 kV/mm dielectric strength

Signal integrity in neural implants

Chemical Resistance

Resistant to virtually all solvents and acids

Stable in sterilization and cleaning processes

Weather Resistance

Stable from -200°C to +260°C

Reliable in sterilization (EtO, gamma, autoclave)

Flame Retardancy

UL94 V-0 rated

Enhanced safety in electrosurgical environments

Optimal Lubricity

PTFE has one of the lowest coefficients of friction of any solid material, typically between 0.04 and 0.10 depending on load and speed. For catheter-based interventions, this means reduced insertion force, less patient discomfort, and lower risk of vessel perforation during complex navigation. When etched and combined with FEP over-tubing, this lubricity is maintained while bonding strength is significantly improved.

Biocompatibility

PTFE is classified as a biologically inert material and has been used in implantable devices since the 1950s. It does not trigger inflammatory responses, does not absorb proteins readily, and is resistant to bacterial adhesion. PTFE Etched Tubes used in cardiovascular and neural applications must meet ISO 10993 biocompatibility standards, which evaluate cytotoxicity, sensitization, and systemic toxicity—criteria that PTFE consistently satisfies.

Dielectric Insulation

With a dielectric constant of approximately 2.1 and dielectric strength near 60 kV/mm, PTFE Etched Tube provides excellent electrical insulation. This is critical in neural stimulation leads and electrophysiology catheters, where signal leakage could compromise device performance or cause unintended tissue stimulation.

Chemical Resistance

PTFE is chemically inert to nearly all known solvents, acids, and bases—including concentrated sulfuric acid, hydrofluoric acid, and most organic solvents. This makes PTFE Etched Tubes compatible with aggressive sterilization agents and contrast media used in imaging-guided procedures. Device manufacturers benefit from longer shelf life and stable performance across multiple sterilization cycles.

Weather and Temperature Resistance

PTFE maintains its mechanical and chemical properties across an exceptional temperature range, from -200°C to +260°C. This stability means devices retain their dimensional accuracy and surface properties through ethylene oxide (EtO), gamma irradiation, and autoclave sterilization—all common methods in medical device manufacturing.

Flame Retardancy

PTFE achieves a UL94 V-0 flame retardancy rating, meaning it self-extinguishes within 10 seconds after a flame source is removed and does not drip flaming particles. In electrosurgical and energy-based catheter applications, this property is a critical safety factor, especially in operating room environments where ignition risks must be minimized.

PTFE Etched Tube vs. Other Catheter Liner Materials

Device engineers often compare PTFE with alternative liner materials. The table below provides a direct comparison:

Table 2: Material comparison for catheter inner liner applications

Material

Friction Coefficient

Biocompatibility

Max Temp (°C)

Chemical Resistance

Bondability (Etched)

PTFE (Etched)

0.04–0.10

Excellent

260

Excellent

High (after etching)

FEP

0.10–0.20

Good

200

Good

Moderate

Nylon (PA)

0.15–0.40

Good

120

Moderate

High

PEEK

0.35–0.45

Excellent

250

Good

High

PTFE's combination of the lowest friction and broadest chemical resistance, paired with post-etching bondability, makes it the preferred choice for inner catheter liners—particularly in complex, minimally invasive procedures where guide wire performance is critical.

Design Considerations When Specifying PTFE Etched Tube

Engineers specifying PTFE Etched Tube for catheter or implant applications should evaluate the following parameters:

Wall thickness: Thinner walls (e.g., 0.001"–0.003") reduce the outer diameter footprint while maintaining lubricity; critical for high-French-count catheter designs.

Etching depth and uniformity: Insufficient etching reduces adhesion to FEP or adhesive layers; over-etching can compromise mechanical properties. Consistent surface activation across the tube length is essential.

Dimensional tolerances: Inner and outer diameter tolerances directly affect lumen patency and compatibility with guide wires (e.g., 0.014", 0.018", 0.035" standard sizes).

FEP heat-shrink compatibility: Shrink ratio, shrink temperature, and wall thickness of the FEP over-tubing must be matched to the PTFE liner to ensure a consistent, void-free bond.

Sterilization method: PTFE is compatible with EtO, gamma, and e-beam sterilization, but device manufacturers should validate that the specific tube lot maintains dimensional stability post-sterilization.

Why Choose LINSTANT for PTFE Etched Tube Manufacturing

LINSTANT operates nearly 20,000 square meters of cleanroom manufacturing space, fully compliant with GMP requirements—an essential foundation for producing medical-grade PTFE Etched Tubes that meet the stringent requirements of cardiovascular and neurosurgical device makers.

Our production infrastructure is purpose-built for precision fluoropolymer tube manufacturing and includes:

15 imported extrusion lines with diverse screw sizes and single-layer, dual-layer, and three-layer co-extrusion capabilities—enabling tight-tolerance PTFE tube production across a wide dimensional range.

8 dedicated PEEK extrusion lines, reflecting our expertise in high-performance polymer processing that extends to PTFE and fluoropolymer families.

2 injection molding lines, supporting end-component fabrication for complete catheter assembly.

Nearly 100 braiding, coiling, and coating equipment sets, critical for producing reinforced catheter shafts that integrate PTFE liners.

40 welding and forming equipment sets, supporting tip forming, bonding, and assembly operations.

This integrated manufacturing ecosystem means that LINSTANT can support not just the supply of PTFE Etched Tube as a raw material, but also its downstream integration into finished or semi-finished catheter assemblies—reducing supply chain complexity for device OEMs. Our capacity ensures reliable order fulfillment even for high-volume or multi-SKU programs, making LINSTANT a strategic manufacturing partner for global medical device companies.

PTFE Etched Tube delivers a unique combination of performance properties—optimal lubricity, biocompatibility, dielectric insulation, chemical resistance, temperature stability, and flame retardancy—that no other single material currently matches for catheter inner lumen applications. Whether used in cardiac catheterization, vascular stent delivery, or neural implants, the etched surface enables reliable bonding with FEP heat-shrink tubing, transforming a notoriously non-adhesive material into a precision-engineered, bondable liner. As minimally invasive procedures continue to grow in complexity and patient populations expand globally, the demand for high-performance PTFE Etched Tube will only increase.

English

English  Français

Français  Español

Español  简体中文

简体中文

简体中文

简体中文