In the field of modern medical device manufacturing, medical heat shrink tubing, as a key functional material, has a wide range of applications, from simple instrument protection to complex interventional treatment systems. Based on clinical needs and material characteristics, medical heat shrink tubing is mainly divided into several types, including polyester (PET), fluoroplastics (FEP/PTFE), polyolefin, and polyether block amide (Pebax).

Content

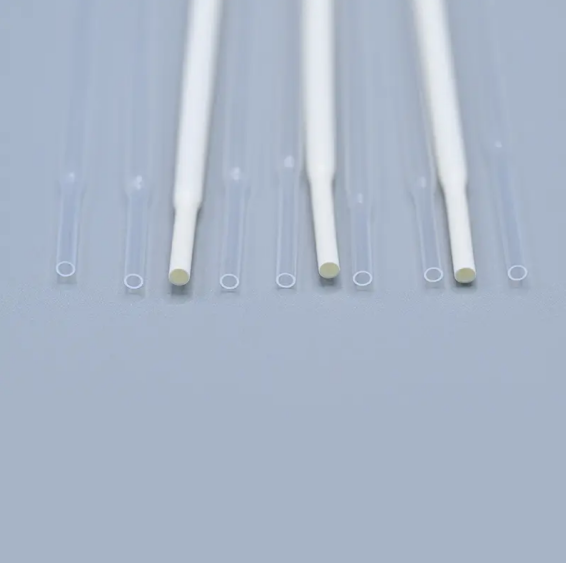

Main Material Classifications of Medical Heat Shrink Tubing

Due to the almost stringent safety requirements for medical devices, high-quality medical heat shrink tubing must be manufactured in a GMP-compliant environment and meet biocompatibility standards. The following are some of the mainstream material types in the industry:

1. Polyester (PET) Heat Shrink Tubing

PET material is known for its ultra-thin wall thickness and high tensile strength.

Features: Possesses extremely high tensile strength and excellent electrical insulation.

Typical applications: It is the preferred choice for minimally invasive interventional surgical instruments, often used for the protection of dilation balloons and ultra-thin coating of catheter surfaces.

2. Fluoroplastic (FEP/PTFE) Heat Shrink Tubing

This type of medical heat shrink tubing mainly addresses the two core needs of "lubrication" and "temperature resistance".

FEP type: Extremely high transparency, often used as a temporary heat shrink mold during catheter processing.

PTFE type: Has a very low coefficient of friction, widely used in guidewire sheaths to ensure smooth advancement of instruments within blood vessels.

3. Polyolefin Heat Shrink Tubing

As one of the most widely used basic materials, polyolefin achieves an excellent balance between cost and performance.

Features: Excellent flexibility, moderate shrinkage temperature, and good resistance to various sterilization methods.

Typical applications: Anti-slip coating for surgical instrument handles and insulation layers for electrosurgical instruments.

4. Polyether Block Amide (Pebax) Heat Shrink Tubing

Pebax material combines the strength of polyamide and the flexibility of polyether.

Features: By adjusting the hardness level, it can assist catheters in achieving a precise transition from proximal pushability to distal flexibility.

LINSTANT: Expert in Professional Medical Tubing Manufacturing

When choosing high-quality medical heat shrink tubing, the manufacturing capabilities of the producer are crucial. As a leading manufacturer in the industry, LINSTANT boasts nearly 20,000 square meters of cleanroom facilities, fully compliant with GMP standards, ensuring the sterility and high cleanliness of its products from the source.

To meet diverse customization needs, LINSTANT is equipped with state-of-the-art production facilities:

- Diverse Extrusion Capabilities: With 15 imported extrusion production lines, covering various screw sizes, and capable of single-layer, double-layer, and triple-layer co-extrusion.

- High-Performance Material Processing: Features 8 dedicated PEEK extrusion production lines and 2 injection molding production lines.

- Complete Supply Chain Support: Possesses nearly 100 sets of weaving/spring/coating equipment and 40 sets of welding and forming equipment.

These powerful manufacturing resources ensure that LINSTANT can achieve efficient order fulfillment, providing global medical device customers with comprehensive solutions from precision extrusion to finished product molding.

Key Performance Indicators of Medical Heat Shrink Tubing

Engineers typically focus on the following dimensions when selecting medical heat shrink tubing:

- Shrink Ratio: Common specifications range from 1.5:1 to 4:1, determining the tubing's ability to cover irregularly shaped surfaces.

- Longitudinal Change: Refers to the percentage change in length after heating. To ensure the precision of instrument assembly, high-quality products require this indicator to be controlled within ±5%.

- Biocompatibility: The material must pass relevant biological evaluations to ensure safety when in contact with human tissue.

- Wall Thickness: With the trend towards miniaturization of interventional devices, ultra-thin wall technology can now reduce thickness to less than 0.005mm.

Understanding the different types of medical heat shrink tubing can help R&D personnel select the most suitable solution during the initial product design phase. Whether pursuing extreme lubrication or ultra-thin walls, choose a partner like LINSTANT with a strong GMP manufacturing background and co-extrusion technology capabilities.

English

English  Français

Français  Español

Español  简体中文

简体中文

简体中文

简体中文