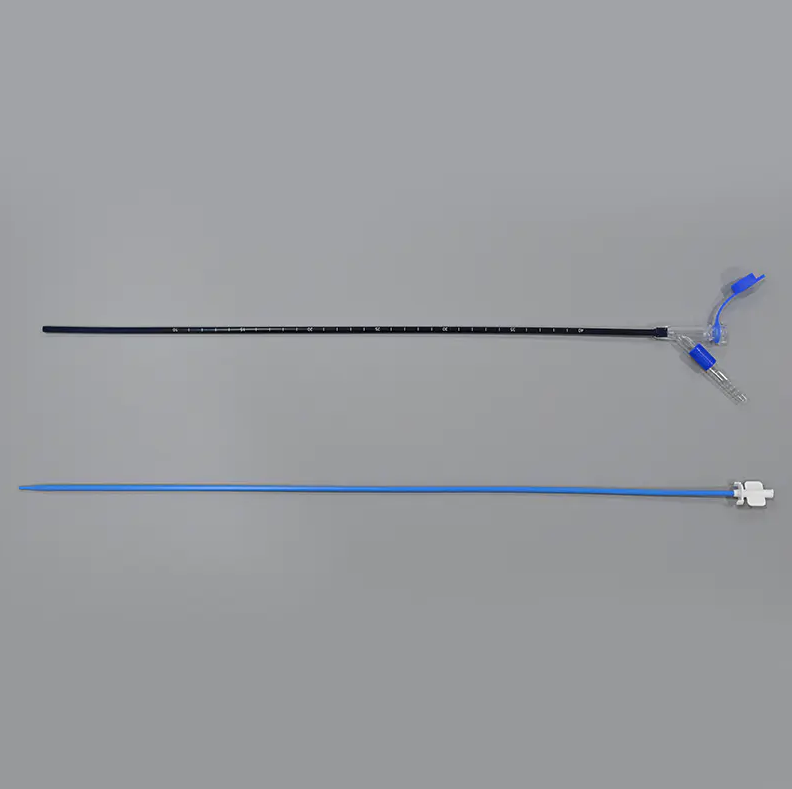

In interventional procedures, guiding catheters are vital "lifelines" connecting the external system to the lesion site. To achieve precise positionin...

READ MOREPRODUCT CATEGORIES

-

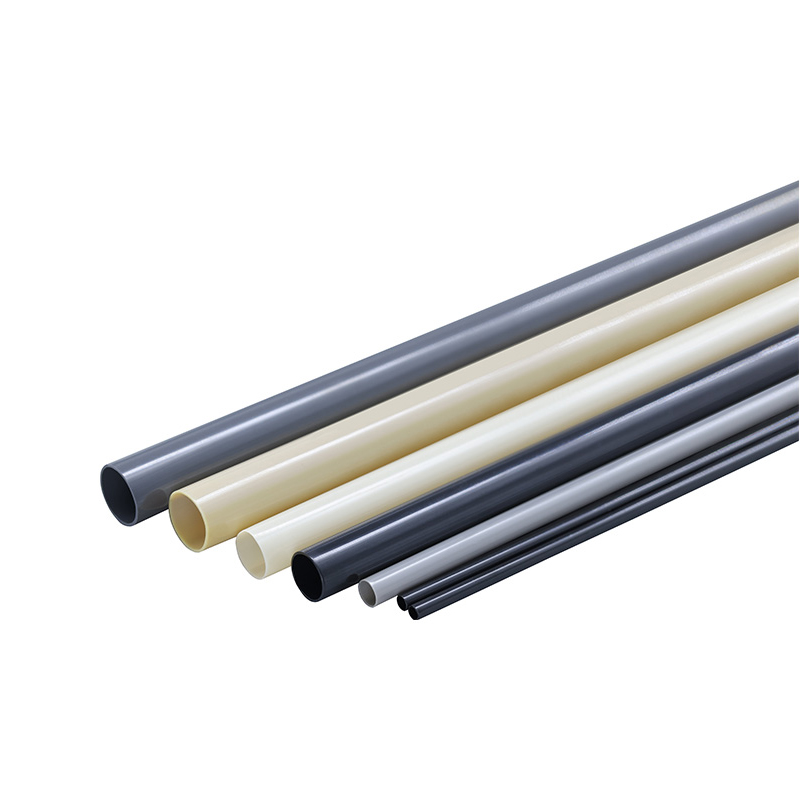

Medical Extruded Tubing

-

Medical Reinforced Tubing

-

Polyimide

-

PEEK

-

Balloon Tubing

-

Micro Catheter

-

Secondary Processes

-

Heat Shrink Tube

-

Fluoropolymer Medical Tubing

-

Endoscope

-

Negative Pressure Access Sheath

-

Guiding Catheter

-

Angiographic Catheter

-

High Pressure Braided Tubing

-

Medical Tubing Surface Treatment Process

OEM/ODM PEEK Manufacturers

-

PEEK Tubing

PEEK material has high temperature tolerance and can operate stably in an environment up to 250 Celsius, while maintaining good mechanical properties, including high strength, high fracture toughness and stable dimensional performance. It also exhibits good chemical stability, flame resistance, wear resistance and good biocompatibility.READ MORE

PEEK Tubing

PEEK material has high temperature tolerance and can operate stably in an environment up to 250 Celsius, while maintaining good mechanical properties, including high strength, high fracture toughness and stable dimensional performance. It also exhibits good chemical stability, flame resistance, wear resistance and good biocompatibility.READ MORE -

PEEK Heat Shrink Tube

PEEK heat shrink tube, crafted from PEEK material, stands out as a high-performance heat shrink tubing among thermoplastic materials. It boasts good resistance to extreme temperatures, high pressure, and corrosive liquids, providing a reliable protective layer that contracts to fit sensitive components and critical connections. Known for its dependable mechanical properties, chemical stability, and biocompatibility, PEEK heat shrink tube finds extensive application across various industries.READ MORE

PEEK Heat Shrink Tube

PEEK heat shrink tube, crafted from PEEK material, stands out as a high-performance heat shrink tubing among thermoplastic materials. It boasts good resistance to extreme temperatures, high pressure, and corrosive liquids, providing a reliable protective layer that contracts to fit sensitive components and critical connections. Known for its dependable mechanical properties, chemical stability, and biocompatibility, PEEK heat shrink tube finds extensive application across various industries.READ MORE -

PEEK Injection Molding

As a high-performance engineering plastic product, PEEK injection molding plays an increasingly important role in modern industry. Its good mechanical properties, high temperature resistance, chemical corrosion resistance and self-lubricating properties make it widely used in many fields.READ MORE

PEEK Injection Molding

As a high-performance engineering plastic product, PEEK injection molding plays an increasingly important role in modern industry. Its good mechanical properties, high temperature resistance, chemical corrosion resistance and self-lubricating properties make it widely used in many fields.READ MORE -

PEEK Machined Parts

PEEK machined parts refer to medical device parts made of PEEK material through mechanical processing. PEEK material has good biocompatibility, mechanical properties and chemical stability, which can meet the high requirements of medical devices for material properties.READ MORE

PEEK Machined Parts

PEEK machined parts refer to medical device parts made of PEEK material through mechanical processing. PEEK material has good biocompatibility, mechanical properties and chemical stability, which can meet the high requirements of medical devices for material properties.READ MORE

English

English  Français

Français  Español

Español  简体中文

简体中文

简体中文

简体中文