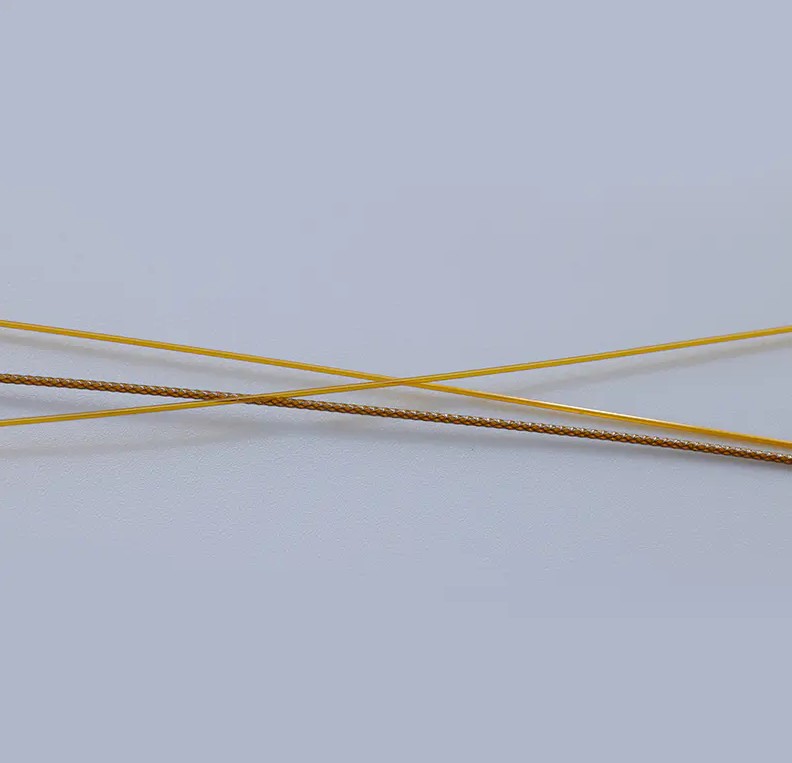

Medical polyimide tubing (PI tubing) is a high-performance material with broad application prospects in the medical field due to its unique physical and chemical properties. It features high toughness, high-temperature resistance, wear resistance, oxidation resistance, and radiation resistance, making it suitable for a wide range of medical devices and instruments.

PI tubing's excellent electrical insulation properties, torque transmission capabilities, high-temperature resistance, ultra-smooth surface and transparency, flexibility and kink resistance, as well as excellent push and pull properties, make it a key component of high-tech products.

The main performance characteristics of medical polyimide tubing (PI tubing) include:

Excellent high-temperature resistance: Polyimide tubing can remain stable at extremely high temperatures, with long-term operating temperatures ranging from -200 to 300°C, and some materials can maintain performance above 400°C.

Good electrical insulation properties: PI tubing has excellent electrical insulation properties, with a dielectric constant of approximately 3.4 and a dielectric strength of at least 120 kV/mm. In addition, its dielectric strength can reach 4000 V/.001", making it suitable for medical devices requiring high insulation.

High Mechanical Strength and Toughness: PI tubing has high tensile strength (minimum 20,000 PSI) and excellent fatigue resistance, making it suitable for medical devices that must withstand high pressure and tension.

Ultra-Smooth Surface: The smooth inner surface of PI tubing is less susceptible to adhesion, making it suitable for liquid transport and preventing clogging.

Biocompatibility: PI tubing has excellent biocompatibility and complies with ISO 10993 and USP. Class VI biocompatibility requirements make it suitable for medical devices that come into direct contact with the human body.

Chemical Resistance: PI tubing exhibits excellent corrosion resistance to a wide range of chemicals and is suitable for disinfectants and chemicals commonly used in medical environments.

Low Friction: PI tubing's low coefficient of friction helps reduce resistance during operation, improving device flexibility and operational efficiency.

Lightweight and Flexible: PI tubing is lightweight, flexible, and kink-resistant, making it suitable for medical devices requiring high flexibility.

Processability: PI tubing is easy to cut, bend, and connect, facilitating the manufacture and installation of medical devices.

Radiation Resistance: PI tubing exhibits excellent radiation resistance and is suitable for applications requiring high radiation resistance. Medical applications.

What does biocompatibility of PI tubing mean? How is biocompatibility achieved?

The biocompatibility of PI tubing refers to its ability to elicit an appropriate and safe host response when in contact with human tissue or body fluids. Specifically, this means that the PI material does not cause adverse reactions such as toxicity, irritation, inflammation, allergy, coagulation, or hemolysis in medical applications, while also interacting well with biological systems, thus supporting its long-term use in medical devices.

Biocompatibility assessment involves multiple aspects, including in vitro and in vivo testing. In vitro testing typically includes cytotoxicity testing, blood compatibility testing (such as anticoagulant and antihemolytic properties), and immune response testing.

For example, studies of the This study demonstrates that PI has no cytotoxic effects on mouse fibroblasts, human retinal pigment epithelial cells, and human brain microvascular endothelial cells. Furthermore, PI materials exhibit excellent blood compatibility, meaning they do not cause hemolysis or coagulation.

In vivo experiments further validate the biological responses of PI materials in living environments. For example, some commercial PI materials have undergone in vivo studies to confirm their compatibility with living organisms. These studies typically involve testing for acute systemic toxicity, irritation, pyrogenicity, sensitization, immune system response, and long-term implantation.

Biocompatibility depends not only on the chemical properties of the material itself but also on a variety of factors, including its physical properties, processing techniques, surface treatment, and degradation products in the body. Impact.

For example, the simplified synthesis and manufacturing process of poly(Iotaly Polymer) materials reduces the number of leachable sources, thereby improving their biocompatibility. Furthermore, their chemical resistance and tolerance to routine sterilization ensure their widespread application in the medical field.

Biocompatibility assessments typically adhere to the requirements of the International Organization for Standardization (ISO) 10993 and the national standard GB/T 16886. These standards cover the entire material lifecycle, from design to market approval, and emphasize the interaction between the material and the biological framework.

When assessing biocompatibility, factors such as the material's shape, size, surface roughness, residual toxic low-molecular substances, processing contamination, and in vivo degradation products need to be considered.

English

English  Français

Français  Español

Español  简体中文

简体中文

简体中文

简体中文