In the medical field, the requirements for cables and pipes are extremely stringent. They must not only provide excellent electrical insulation and physical protection, but also meet special requirements such as biocompatibility, high-temperature sterilization resistance, and precision assembly. Medical heat shrink tubing, due to its unique properties, plays a vital role in medical device manufacturing. The following describes the correct use of heat shrink tubing to help you achieve optimal results in medical applications.

Content

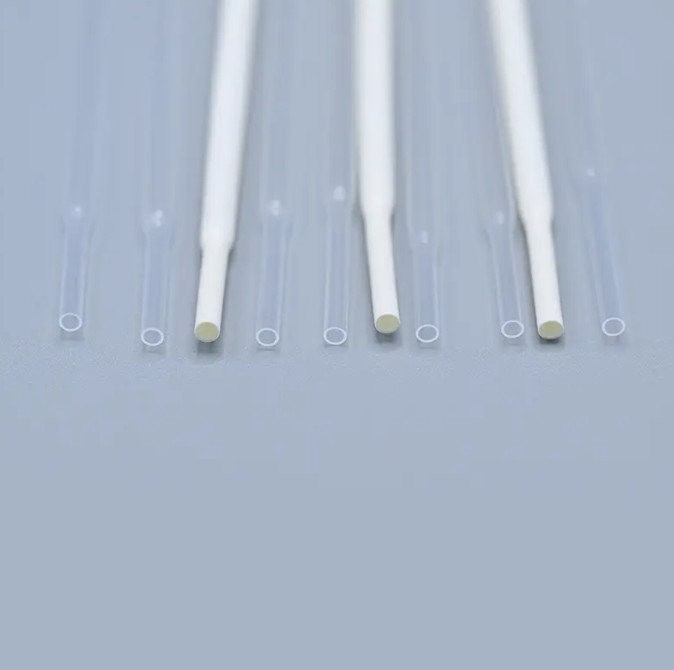

Main Types of Heat Shrink Tubing

There are many types of heat shrink tubing, which can be categorized by material, shrink ratio, and application. Common ones include:

Polyolefin heat shrink tubing

The most widely used, offering excellent insulation, chemical resistance, and mechanical protection.

Fluoropolymer heat shrink tubing (such as PTFE and PVDF)

High-temperature and chemical resistance, low friction coefficient, suitable for precision medical equipment.

Double-wall heat shrink tubing (with adhesive)

Contains an inner layer of hot melt adhesive. When heated and shrinks, the adhesive fills gaps, providing waterproof and moisture-proof sealing.

Silicone rubber heat shrink tubing

Soft and flexible, with excellent biocompatibility, it's suitable for devices that require bending or expansion.

What is heat shrink tubing?

Heat shrink tubing is a tubular material that shrinks when heated. Common materials include polyolefins, fluoropolymers, and silicone rubber. During the production process, the material undergoes radiation cross-linking, heat expansion, and cooling to set the shape, allowing it to remain in its expanded state at room temperature. When heated again, the tubing shrinks back to its original size, tightly wrapping the object inside.

In medical devices, heat shrink tubing is commonly used for:

- Electrical insulation and protection: Coating wires and connectors to prevent short circuits and mechanical damage.

- Biocompatible coating: Used on devices such as catheters and guidewires, it provides a smooth, non-toxic protective layer to reduce friction.

- Mechanical protection: Protects delicate components such as optical fibers and sensors from bending, abrasion, and chemical corrosion.

- Color identification: Different colors are used to distinguish the function of cables or tubing.

Preparing for Use

- Select the Right Size: Before shrinking, the inner diameter should be 20%–50% larger than the maximum outer diameter of the object being covered. After shrinking, it should be slightly smaller than or equal to the outer diameter to ensure a tight fit.

- Clean Surface: Ensure the surface is clean, dry, and free of oil and dust, especially for heat shrink tubing with adhesive, to ensure a secure fit after shrinking.

- Smooth Cutting: Use scissors or a utility knife to cut the desired length. The cut should be straight and free of burrs.

Proper Heating Method

- Even Heating: Adjust the heat gun temperature to an appropriate range. Start at one end and move slowly, heating evenly to avoid overheating.

- Observe Changes: During heating, the tubing will gradually shrink and adhere to the surface, resulting in a smooth, wrinkle-free surface. For heat shrink tubing with adhesive, a small amount of adhesive may overflow from the end.

- Cooling and Setting: After heating, allow the tubing to cool naturally to room temperature. Avoid touching or moving the tubing during this time.

Precautions for Medical Applications

- Material Compliance: Select materials that meet ISO 10993 biocompatibility standards, such as medical-grade polyolefins, fluoropolymers, or silicone rubber.

- Clean Operation: It is recommended to operate in a cleanroom or controlled environment to prevent dust and microbial contamination.

- Sterilization Compatibility: Ensure that the heat shrink tubing can withstand high-temperature steam sterilization, ethylene oxide sterilization, or gamma irradiation sterilization without affecting performance.

English

English  Français

Français  Español

Español  简体中文

简体中文

简体中文

简体中文