In the precision manufacturing of medical devices, material performance requirements are extremely stringent. PI Reinforced Tubing has become a key component in demanding applications such as vascular intervention and electrophysiology.

Content

Overview of PI Material

PI, also known as polyimide, is a recognized high-performance organic polymer. Its outstanding features include:

- High strength: Even at microscale, PI maintains excellent mechanical strength.

- Excellent temperature resistance and thermal stability: This allows it to operate stably in a variety of complex medical environments, including high- and low-temperature sterilization processes.

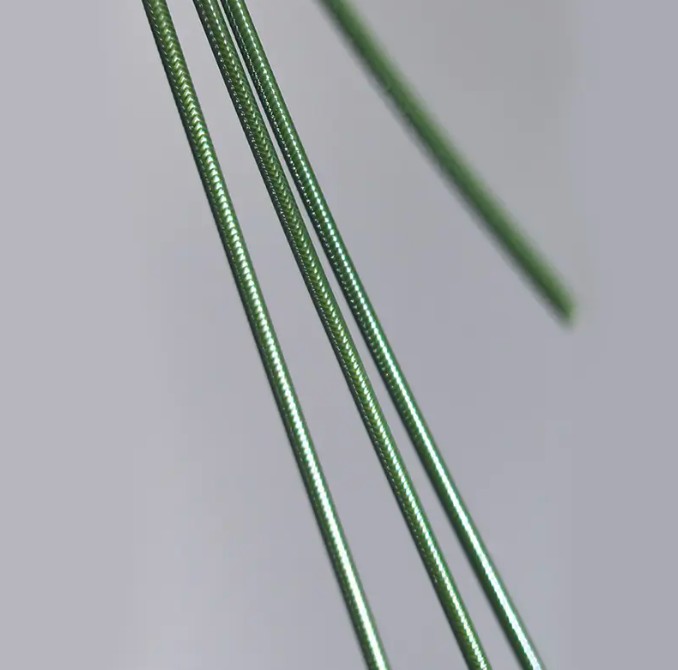

Although simple PI tubing offers excellent performance, braided reinforcement has been introduced to meet the higher demands of pushability, torsion resistance, and pressure resistance within the body for medical catheters.

Braided Reinforcement Technology

Braided reinforcement is a key production technology that incorporates a precisely woven reinforcement layer (usually metal wire or fiber) within the tubing wall to significantly:

- Improve compressive resistance: This prevents the tubing from deforming or collapsing when bent or subjected to external pressure.

- Improve pushability: This ensures that the catheter can effectively transmit force from the outside to the tip, enabling precise control by the physician.

LINSTANT: A Professional Manufacturer of High-Performance Polyimide Reinforced Tubing

Manufacturing PI Reinforced Tubing that meets the highest medical standards requires sophisticated polymer catheter extrusion, coating, and post-processing technologies.

Since its establishment in 2014, LINSTANT has dedicated itself to this endeavor. We are committed to providing medical device manufacturers with precise, safe, and diverse process development capabilities and stable output. We understand the importance of high precision in life sciences and have amassed extensive experience in tubing extrusion using specialized engineering materials such as polyimide (PI) and PEEK.

Product Scope and Capabilities

Our business scope covers several key areas of medical catheter manufacturing, including extruded single- and multi-layer tubing, single- and multi-lumen tubing, and single-, double-, and triple-layer balloon tubing, as well as a variety of surface treatment solutions. We offer a wide range of sizes to meet the complex customization needs of medical device customers for PI Reinforced Tubing and related catheter components.

Key Advantages of Polyimide Reinforced Tubing

Our polyimide reinforced tubing perfectly combines the inherent advantages of polyimide (PI) with the mechanical properties of braid reinforcement, resulting in a composite tubing with superior overall performance. Key features include:

- Improved Torque Control: The tip of the catheter responds more precisely and instantly to external rotation, crucial for precision in minimally invasive procedures.

- Excellent Flexibility: Easily navigates the complex, tortuous vascular pathways of the human body.

- High Strength: Ensures resistance to damage during operation.

Thanks to these advantages, PI Reinforced Tubing are widely used in numerous medical devices and are a key enabler for minimally invasive interventional procedures. Key applications and related medical devices include:

| Application Areas | Typical Medical Devices (Related Terms) |

| Vascular | Intravascular ultrasound catheters, vascular stent delivery systems |

| Structural Heart Disease | Delivery sheaths, interventional catheters |

| Electrophysiology | Electrophysiology catheter sheaths |

| Urology | Lithotomy basket sheaths, urinary catheters |

English

English  Français

Français  Español

Español  简体中文

简体中文

简体中文

简体中文