Content

Why does medical device manufacturing favor medical polyimide tubing?

Polyimide is a polymer material with an imide structure. In the medical field, the requirements for materials are extremely stringent, and medical polyimide perfectly meets these needs:

Excellent mechanical strength: Ensures that the catheter has sufficient thrust and bending resistance during interventional procedures, enabling precise manipulation.

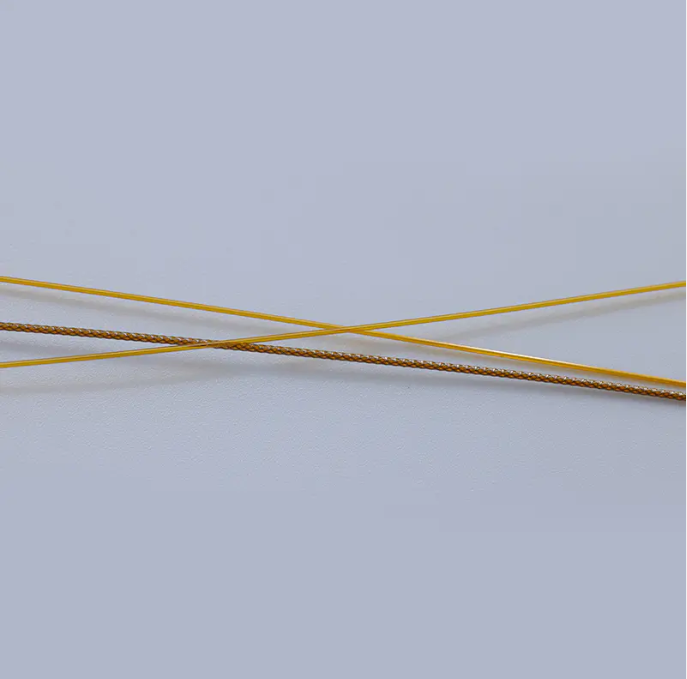

Ultra-thin wall thickness and flexibility: Enables the production of tubing with extremely thin walls, reducing the catheter's outer diameter while maintaining strength, facilitating passage through narrow and tortuous blood vessels.

Heat resistance and chemical stability: Adapts to the high-temperature sterilization and various chemical processing processes commonly encountered in medical device manufacturing. These properties are what answer the core value of the question, "What are the uses of polyimide?"—providing reliable performance assurance for complex and precise medical devices.

Core Uses of polyimide tubing: Key to Interventional Therapy

Your company's medical polyimide tubing is primarily used in various catheters and delivery systems. Specific application scenarios are as follows:

1. Cardiovascular Field: Vascular, Structural Heart Disease, and Electrophysiology

In cardiovascular interventional procedures, the precision and safety of catheters are crucial:

Electrophysiology Catheters: Medical polyimide, used as the outer tubing or inner lining of electrophysiology catheters, provides excellent insulation and flexibility for the diagnosis and ablation of cardiac arrhythmias.

Vascular Stent Delivery Systems: Polyimide tubing is the preferred material for the outer tubing of stent delivery systems, providing the necessary rigidity and delivery force to ensure precise stent delivery to the lesion site.

2. Endoscopic Catheters: Precise Diagnosis and Minimally Invasive Surgery

Endoscopes require deep insertion into human cavities for observation and manipulation.

Endoscopic Catheters: The superior properties of polyimide allow for thinner catheter walls and smaller outer diameters, improving patient comfort while ensuring catheter flexibility and ease of passage.

3. Urological Instruments: Ensuring Complex Procedures

In the field of urology, for example, in the treatment of kidney stones and ureteral stones:

Stone Retrieval Basket Outer Tube: Medical-grade polyimide tubing serves as the outer protective tube for instruments such as stone retrieval baskets. It possesses excellent anti-kink and abrasion resistance, ensuring smooth stone grasping and removal.

Process Control and Market Trends

To fully unleash the potential of polyimide materials in the medical field, extremely high levels of process control are required. Since its founding in 2014, LINSTANT has focused on the extrusion, coating, and post-processing technologies of medical polymer tubing. We remain committed to providing precise, safe, and diversified process development capabilities and stable production volumes, ensuring that every piece of medical-grade polyimide tubing meets the most stringent medical standards.

With the increasing global aging trend and the widespread adoption of minimally invasive interventional surgery, the market demand for high-performance medical polyimide tubing will continue to rise. In the future, polyimide materials will develop towards higher precision, thinner wall thickness, and more multi-cavity structures to support more complex and delicate interventional surgical instruments.

English

English  Français

Français  Español

Español  简体中文

简体中文

简体中文

简体中文