Flaring or tipping medical PEEK Tubing is primarily achieved through precision thermal processing. Due to PEEK's (polyether ether ketone) extremely high melting point (approximately 343°C), traditional cold working methods cannot permanently deform it. The typical process involves placing the catheter end in a precisely temperature-controlled induction heating coil. Once the material reaches its softening point, a precision mandrel or mold is used to physically extrude and shape it.

As a professional medical device component partner, LINSTANT, with its advanced production facilities, ensures that every medical PEEK Tubing catheter maintains excellent biocompatibility and mechanical strength after shaping.

Content

Why are the forming processes for medical PEEK Tubing so demanding?

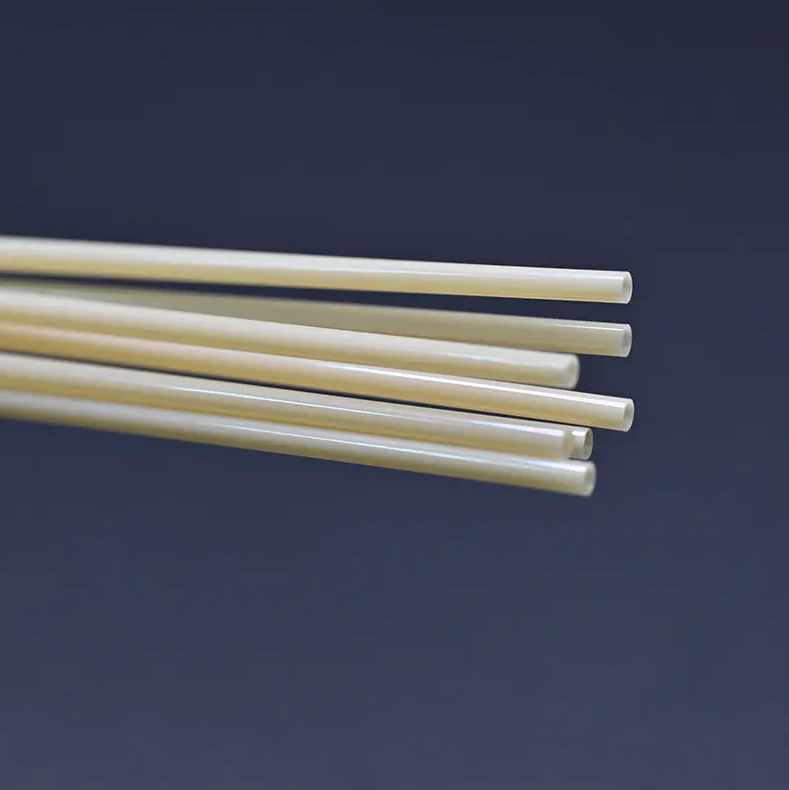

In the medical device manufacturing field, medical PEEK Tubing are known for their excellent strength-to-weight ratio and chemical inertness. However, achieving perfect secondary processing (such as flaring or welding) requires stringent requirements on the original extrusion quality of the tubing.

LINSTANT has nearly 20,000 square meters of cleanroom space, fully compliant with GMP requirements. We understand that even the slightest dust particle or impurity can lead to cracks during the thermoforming process. Through eight dedicated PEEK extrusion production lines, we can provide global customers with dimensionally stable, highly pure, high-performance tubing, addressing the pain points of carbonization and brittleness during the forming process.

Core Technical Steps in Medical PEEK Catheter Forming

In the design of cardiovascular intervention or endoscopic instruments, the following fine processing of medical PEEK Tubing is usually required:

1. Mold Forming (Tipping & Flaring)

Flaring: Expanding the end of the tubing for connection with Luer connectors.

Tipping: Shaping the end of the tubing into a rounded bullet shape to reduce trauma when entering the human body.

2. Integrated Reinforcement Technology

For complex medical device designs, LINSTANT's 40 sets of welding and molding equipment and nearly 100 sets of weaving/spring equipment can be used in conjunction with PEEK tubing. We can combine PEEK/PI tubing with spiral or braided reinforcement sheaths, achieving a perfect multi-material transition through welding technology.

LINSTANT: Your One-Stop Medical Tubing Manufacturing Expert

Choosing the right medical PEEK Tubing catheter manufacturer is not just about purchasing raw materials, but also about choosing a guarantee of efficient order fulfillment. LINSTANT's business scope includes:

- Precision Extrusion: With 15 imported extrusion production lines, covering single-layer, double-layer, and triple-layer co-extrusion capabilities, we can produce single-lumen or multi-lumen tubing.

- Diversified Materials: In addition to special engineering materials such as PEEK/PI tubing, we also provide single-layer/multi-layer balloon tubing and surface treatment solutions.

- Integrated Manufacturing: Combining 2 injection molding production lines, we provide customers with integrated support from tubing extrusion to injection molded accessories.

Mastering the flaring and molding technology of medical PEEK Tubing is key to improving the performance of interventional devices. Leveraging LINSTANT's strong production scale and precision processing equipment, we can provide you with comprehensive support from high-performance tubing customization to post-processing welding and molding.

English

English  Français

Français  Español

Español  简体中文

简体中文

简体中文

简体中文