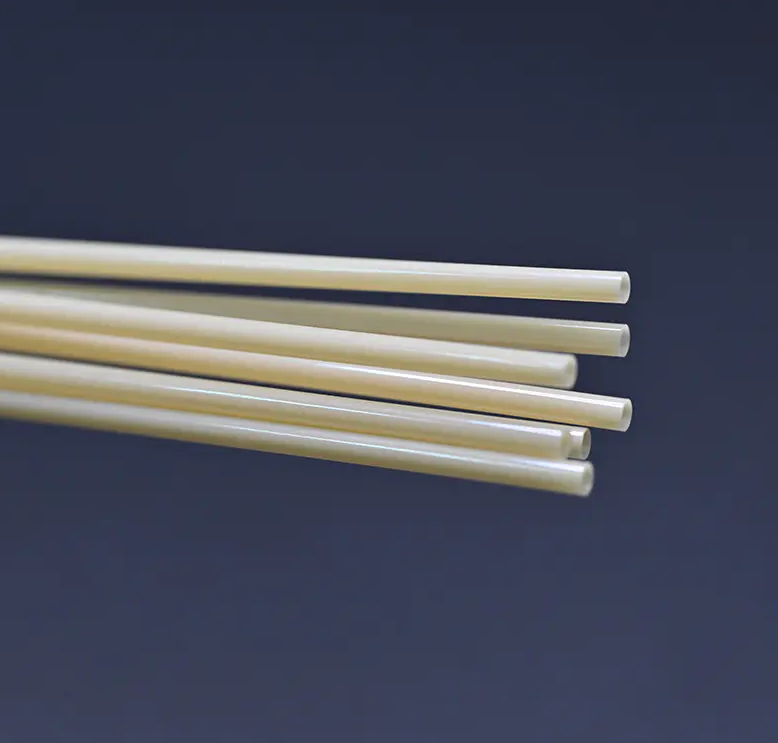

PEEK tubing (polyether ether ketone tubing) is highly favored in laboratory analysis, medical device manufacturing, and aerospace engineering due to its exceptional performance. This high-performance polymer can withstand high temperatures up to 250°C (and even 260°C for short periods) and possesses excellent chemical stability and mechanical properties. However, due to the hardness and high toughness of PEEK material, achieving precise and smooth cuts presents a challenge for many engineers.

Content

Why is the Cutting Quality of PEEK Tubing Important?

Whether used in high-performance liquid chromatography (HPLC), precision medical catheters, or military aerospace applications, the cutting quality of PEEK tubing directly impacts its effectiveness:

- Reduced dead volume: In analytical instruments, uneven cuts can lead to dead volume at the connection points, causing signal peak broadening or experimental errors.

- Ensured sealing: Vertical and smooth cuts ensure a tight seal between the tubing and connectors, preventing leaks under high-pressure conditions.

- Maintaining biocompatibility: Professional cutting methods prevent the generation of debris, ensuring the biocompatibility of PEEK tubing in medical applications (such as cardiovascular, spinal surgery, and endoscopy).

Common PEEK Tubing Cutting Methods and Professional Equipment

1. Using a Dedicated Tube Cutter (Preferred for Laboratories)

Dedicated tube cutters are usually equipped with a V-groove to securely hold the PEEK tubing, ensuring the blade cuts perpendicularly.

Operating tips: Apply even pressure during cutting and avoid rotating the tube to prevent spiral patterns on the cut surface.

2. Automated Precision Extrusion and Cutting (Preferred for Industrial Applications)

For large-scale production, more advanced facilities are required. LINSTANT has nearly 20,000 square meters of cleanroom space, fully compliant with GMP requirements.

We are equipped with 8 dedicated PEEK extrusion production lines, capable of producing tubing with high strength, high fracture toughness, and dimensional stability.

With 40 sets of welding and molding equipment, we can achieve precise length control and end-face treatment directly in the production process, ensuring that every inch of PEEK tubing meets stringent standards.

3. Laser Cutting Technology

For extremely fine or complex-shaped medical catheters (such as urological catheters and electrosurgical forceps sheaths), laser cutting offers non-contact, ultra-high precision.

About LINSTANT: Your High-Performance Tubing Partner

When addressing the application challenges of PEEK tubing, choosing a supplier with strong production capabilities is crucial. LINSTANT not only focuses on the cutting process but also maintains strict control at the source of production:

- Strong Production Scale: We have 15 imported extrusion production lines (covering single-layer, double-layer, and triple-layer co-extrusion capabilities), and 2 injection molding production lines.

- Full-Chain Support: We have nearly 100 sets of weaving, spring, and coating equipment, enabling us to provide customized solutions for different application scenarios such as electrocoagulation forceps and orthopedic trauma care.

- Efficient Delivery: Our comprehensive equipment matrix ensures efficient fulfillment capabilities even for complex orders.

Precautions During the Cutting Process

When handling PEEK tubing, its material characteristics should be fully considered:

- Avoid using ordinary scissors: Ordinary scissors will compress the tube wall, causing deformation and oval-shaped cuts that severely affect fluid flow.

- Maintain cleanliness: As PEEK is often used in trauma care and orthopedic surgery, the cutting environment and tools should be kept clean to avoid cross-contamination.

- Pay attention to dimensional stability: Although PEEK has excellent dimensional stability, extra care is required when cutting extremely thin-walled tubes to prevent collapse.

Correctly cutting PEEK tubing is the crucial first step in leveraging its high-temperature resistance, wear resistance, and flame-retardant properties. Whether you need precise cutting of a single tube or are looking for a large-scale customized production partner, LINSTANT can provide professional support that meets GMP standards. Avoid using ordinary scissors for cutting, as this will damage the roundness of the PEEK tube.

English

English  Français

Français  Español

Español  简体中文

简体中文

简体中文

简体中文